PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Galvanized steel wire is made by drawing high-quality carbon structural steel such as 45#, 65#, 70#, and then galvanizing (electrogalvanizing or hot-dip galvanizing).

Galvanized steel wire is carbon steel wire coated with zinc by hot-dip or electroplating. Its properties are similar to those of straightened and tempered steel wire. It can be used as unbonded prestressing tendons, but requires a minimum of 200-300g of zinc per square meter. It is commonly used as parallel steel cables in cable-stayed bridges (flexible sheaths are also used as an outer layer of protection).

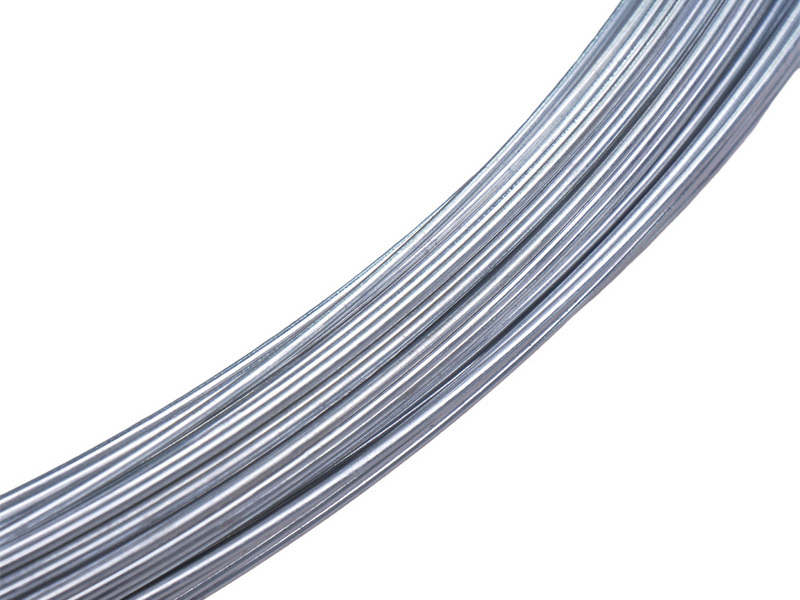

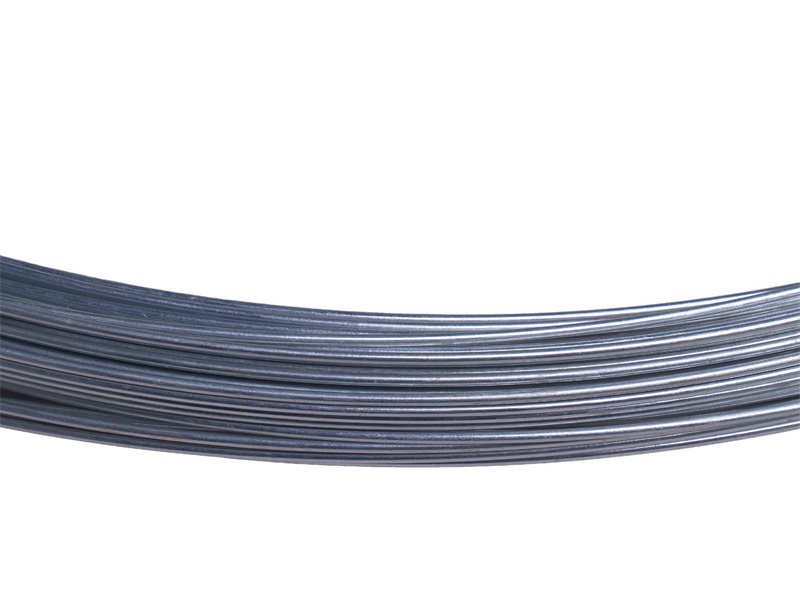

Galvanized steel wire has a smooth, glossy surface free of cracks, knots, burrs, scratches, or rust. The zinc coating is uniform, adheres strongly, offers long-lasting corrosion resistance, and exhibits excellent toughness and elasticity. The tensile strength should be between 900 MPa and 2200 MPa (wire diameter 0.2 mm to 4.4 mm). The twisting capacity (0.5 mm) should be at least 20 times, and the repeated bending capacity should be at least 13 times.

Galvanized steel wire is mainly used in greenhouses, farms, cotton baling, springs, and wire rope manufacturing. It is also suitable for engineering structures with harsh environmental conditions, such as cable-stayed bridge cables and sewage tanks.

High tensile strength galvanized steel wire

The quality of the galvanized coating can be assessed by the weight of the zinc applied to the substrate, the adhesion between the zinc coating and the substrate, and the coating uniformity. Uniformity is a key quality indicator of the galvanized coating. During typical use, corrosion typically begins at the thinnest point of the zinc coating and spreads to the surrounding areas, leading to rust and wire breakage, ultimately shortening the coating's service life.

Galvanized Steel Wire Drawing Process: 1. To improve the performance of galvanized steel wire, the steel wire is lead-quenched, galvanized, and then drawn to a finished product. This is called the "galvanizing-then-drawing" process. 2. "Intermediate galvanizing-then-drawing" involves drawing the lead-quenched steel wire once, galvanizing it, and then drawing it a second time to the finished product, with the galvanizing occurring between the two drawing stages. 3. To produce ultra-high-strength galvanized steel wire (3000 N/mm²), a "hybrid galvanizing-drawing" process is used.