PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Common materials for square steel bars include carbon steel, alloy steel and stainless steel.

Aluminum bar is a high strength heat treatable alloy. It has extremely high strength and resistance to spalling corrosion and stress corrosion cracking. Widely used in aerospace, mold processing, mechanical equipment, fixture and other fields. As a supplier of aluminum alloy bars, we have sufficient inventory, so we can quickly ship according to customer's demand. The company has automatic cutting machine, plasma cutting machine and other deep processing equipment. Aluminum bar specifications can be processed and cut according to customer needs.

Stainless steel bars are made of stainless steel ingots through hot rolling or forging. According to different classification standards, stainless steel bars can be divided into many categories: round steel, square steel, flat steel, hexagonal steel and octagonal steel.

According to the use of rebar classification, divided into ordinary reinforcement and concrete special reinforcement. According to the appearance of the points, divided into with reinforcement and light round reinforcement

Round steel is divided into hot rolling, forging and cold drawing. Carbon steel can be divided into low carbon steel, medium carbon steel and high carbon steel according to chemical composition.

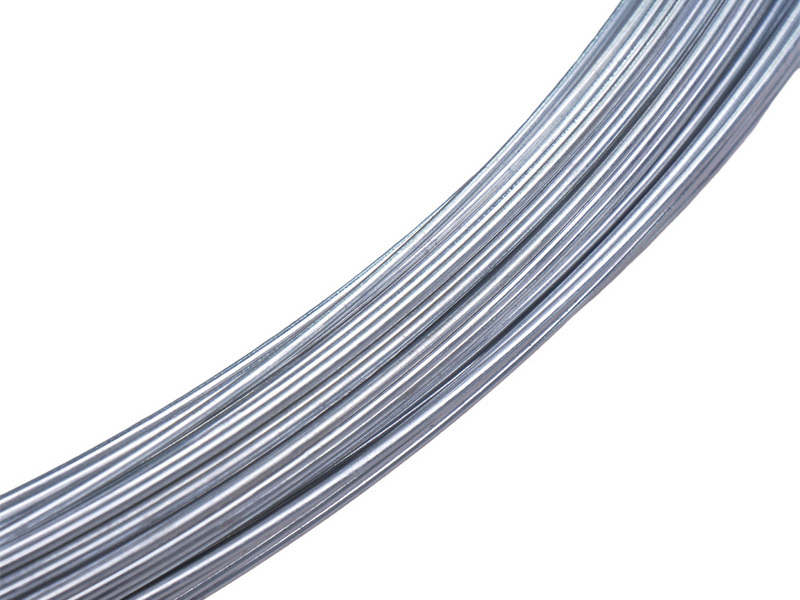

Galvanized steel wire is made by drawing high-quality carbon structural steel such as 45#, 65#, 70#, and then galvanizing (electrogalvanizing or hot-dip galvanizing).

Galvanized steel wire is carbon steel wire coated with zinc by hot-dip or electroplating. Its properties are similar to those of straightened and tempered steel wire. It can be used as unbonded prestressing tendons, but requires a minimum of 200-300g of zinc per square meter. It is commonly used as parallel steel cables in cable-stayed bridges (flexible sheaths are also used as an outer layer of protection).

Galvanized steel wire has a smooth, glossy surface free of cracks, knots, burrs, scratches, or rust. The zinc coating is uniform, adheres strongly, offers long-lasting corrosion resistance, and exhibits excellent toughness and elasticity. The tensile strength should be between 900 MPa and 2200 MPa (wire diameter 0.2 mm to 4.4 mm). The twisting capacity (0.5 mm) should be at least 20 times, and the repeated bending capacity should be at least 13 times.