PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

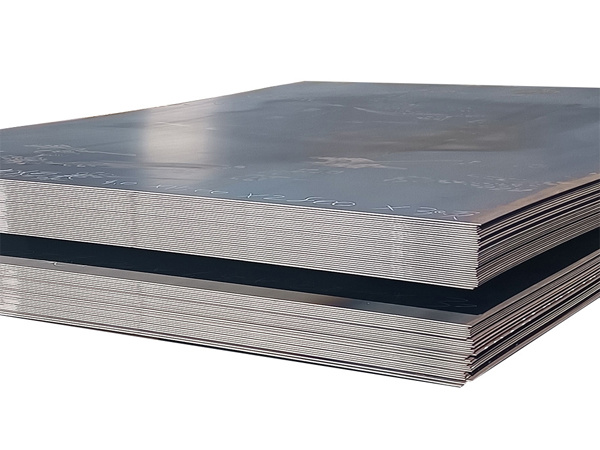

Carbon steel plate refers to the flat steel made by pouring molten steel and after cooling by multi-track rolling mill. The thickness of the steel plate can be divided into thin steel plate < 4 mm (minimum 0.2 mm), medium thickness steel plate 4~60 mm, extra thick steel plate 60~115 mm. The width of the sheet is 500~1500 mm; The width of the thickness is 600~3000 mm. According to steel types, there are ordinary steel, high quality steel, alloy steel, spring steel, stainless steel, tool steel, etc. According to different uses can be divided into cold forming steel, car structural steel, corrosion resistant structural steel, mechanical structural steel, etc. Including high carbon steel, medium carbon steel and low carbon steel in the steel containing sulfur, phosphorus and non-metallic inclusion less than carbon structural steel, mechanical performance is relatively good, average commonly used carbon structural steel, low alloy steel welding steel structure, small steel parts, production of container ships, vehicles, and therefore is widely used in Bridges, buildings, machinery, pressure vessels and other manufacturing industries.

Corten steel plate is a kind of steel made by adding a small amount of corrosion-resistant elements such as copper and nickel to ordinary carbon steel. It has excellent weather resistance and corrosion resistance. Its full name is atmospheric corrosion resistant high-strength low-alloy steel plate, also known as atmospheric corrosion resistant steel or weathering steel. The main components of Corten steel plate include carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), chromium (Cr), nickel (Ni), copper (Cu) and other elements.

Corten steel plate is weather-resistant: Due to its special chemical composition, Corten steel plate can form a protective film in the natural environment to prevent further corrosion, thereby extending its service life. Strength and toughness: Corten steel plate has high tensile strength and yield strength, while maintaining good plasticity and toughness, and is suitable for various engineering structures. Processing performance: It has good welding, cutting and forming performance and is suitable for a variety of processing technologies.

Carbon structural steel plate is an industrial plate made of carbon steel as the base material, which is widely used in construction, machinery manufacturing and other fields.

Alloy steel plate refers to the flat steel made by pouring molten steel and after cooling by multi-track rolling mill. The thickness of the steel plate can be divided into thin steel plate < 4 mm (minimum 0.2 mm), medium thickness steel plate 4~60 mm, extra thick steel plate 60~115 mm. The width of the sheet is 500~1500 mm; The width of the thickness is 600~3000 mm. According to steel types, there are ordinary steel, high quality steel, alloy steel, spring steel, stainless steel, tool steel, etc. According to different uses can be divided into cold forming steel, car structural steel, corrosion resistant structural steel, mechanical structural steel, etc. Including high carbon steel, medium carbon steel and low carbon steel in the steel containing sulfur, phosphorus and non-metallic inclusion less than carbon structural steel, mechanical performance is relatively good, average commonly used carbon structural steel, low alloy steel welding steel structure, small steel parts, production of container ships, vehicles, and therefore is widely used in Bridges, buildings, machinery, pressure vessels and other manufacturing industries.

Hot-rolled steel plate is produced by high-temperature rolling from ingots or continuously cast billets. Typically over 1.2 mm thick, it exhibits excellent plasticity and weldability. The processing includes trimming, cutting, and flattening. Quality is enhanced through precise heating temperature profiles, air-fuel ratio adjustments, and rolling parameter control. Products are categorized as structural steel, weathering steel, and automotive structural steel.

Cold-rolled steel is made from hot-rolled coil, rolled at room temperature below the recrystallization temperature. It is widely used in automobile manufacturing and electrical appliances. While cold rolling is performed at the recrystallization temperature, it is generally understood to be rolling using room-temperature rolled material.